Performa of Antibiota Paints on The Growth of Biofouling Attachment Structures in Indonesian Sea Waters

DOI:

https://doi.org/10.46252/jsai-fpik-unipa.2023.Vol.7.No.3.287Keywords:

Antifouling paint, Biofouling, Corrosion, Copper oxide, Tropical SeaAbstract

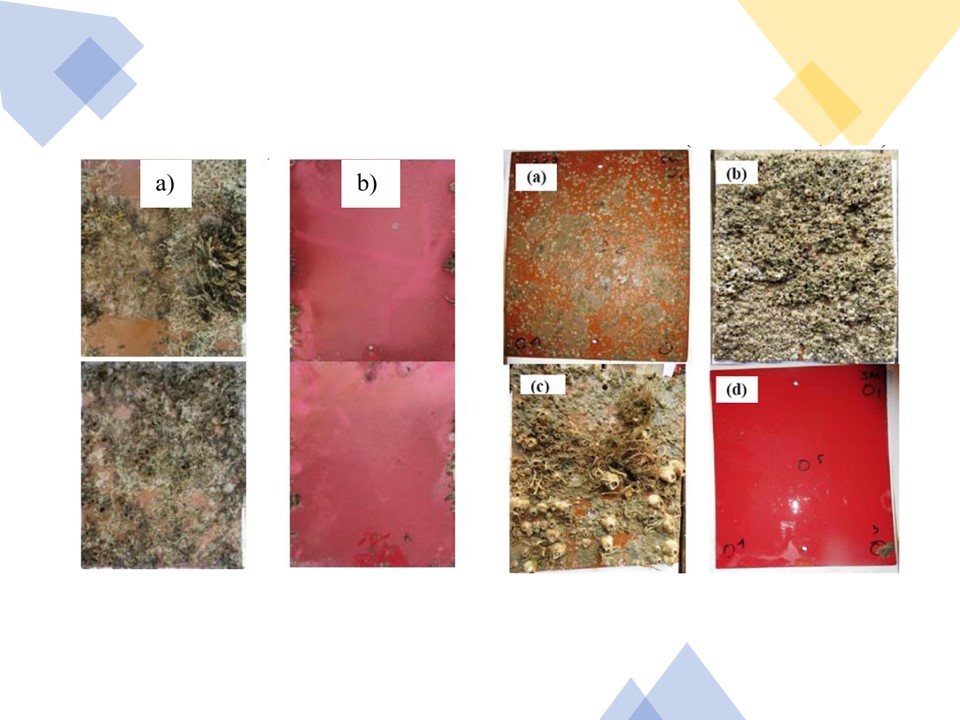

Indonesia has a tropical climate, where seasonal changes are relatively stable every year for surface temperatures and high salinity in the marine environment. The growth of tropical marine biofouling continues uninterrupted throughout the year. However, the metabolic activity of biofouling mostly has a detrimental effect on various submerged marine infrastructures where it damages the physical integrity of the structure, especially the corrosion effect and the tendency to waste marine fuel due to marine biota. In Indonesia, one way to reduce marine biofouling activity is to apply antifouling (AF) paint, which slowly releases antifouling active compounds in AF paint into seawater. Antifouling paint performance investigations have been carried out by the Corrosion Research Group, Metallurgical Research Center-The National Research and Innovation Agency for the last 5 years where the role of physical parameters of seawater and the biocidal active substance of antifouling paints plays a role in extending the service life of antifouling paints that are applied to installed structures in marine waters. The thickness of the antifouling paint and the type of antifouling paint also play a role in maintaining the service life. In Indonesia, antifouling paints still use inorganic heavy metal biocides based on copper oxide (Cu2O) as antifouling agents in marine waters, so further national-scale research is needed to replace copper heavy metals as the main biocide.

Downloads

References

Atlar, M., Callow, M. (2003). The development of foul-release coatings for seagoing vessels. Journal of Marine Design and Operations 4, 11-23.

Breitburg, D., Levin, L.A., Oschlies, A., Grégoire, M., Chavez, F.P., Conley, D.J., Garçon, V., Gilbert, D., Gutiérrez, D. and Isensee, K. (2018). Declining oxygen in the global ocean and coastal waters. Science 359 (6371).

Diego, Y., Kiil, S., Johansen, K.D. (2004). Antifouling technology-past, present and future steps towards efficient and environmentally friendly antifouling coatings. Progress in Organic Coatings, 50, 75-104.

Elviliana, E., Suhartini, S., Hidayat, N., & Oechsner, H. (2022). A mini-review on anaerobic digestion of Indonesian macroalgae biomass: present scenario and future scope. Advances in Food Science, Sustainable Agriculture and Agroindustrial Engineering, 5(2). https://doi.org/10.21776/ub.afssaae.2022.005.02.5

Iswadi, A., Porter, J. S., Bell, M. C., Garniati, L., Harris, R. E., & Priyotomo, G. (2022). Establishing an Agenda for Biofouling Research for the Development of the Marine Renewable Energy Industry in Indonesia. Journal of Marine Science and Engineering (Vol. 10, Issue 3). https://doi.org/10.3390/jmse10030384

Kojima, R., Miyata, O., Shibata, T., Senda, T. (2016). Leaching Phenomena of Antifouling Agents from Ships` Hull Paints. Journal of Shipping and Ocean Engineering 6, 269-278

Laidlaw, F.B. (1952). The history of the prevention of fouling. Marine Fouling and Its Prevention 580, 211–22.

Lagerström, M., Lindgren, J.F., Holmqvist, A., Dahlström, M. and Ytreberg, E. (2018). In situ release rates of cu and zn from commercial antifouling paints at different salinities. Marine Pollution Bulletin 127, 289-296.

Leidonald, R., Muhtadi, A., Lesmana, I., Harahap, Z. and Rahmadya, A. (2019). Profiles of temperature, salinity, dissolved oxygen, and ph in tidal lakes. IOP Conference Series: Earth and Environmental Science, IOP Publishing 260 (1)

Nuraini, L., Prifiharni, S, Priyotomo, G., Sundjono. (2017a). The corrosivity and performance evaluation of antifouling paint exposed in seawater Muara Baru Port, Jakarta. J Phys Conf Ser, 817, 012068.

Nuraini, L., Prifiharni, S., Priyotomo, G., Sundjono, Gunawan, H. (2017b). Evaluation of anticorrosion and antifouling paint performance after exposure under seawater Surabaya-Madura (Suramadu) bridge. AIP Conf Proc 1823, 020101-1-020101-7.

Priyotomo, G. (2022). The behavior of metal release on 430 stainless steel cookware in citric acid solution by cyclic method. AIP Conference Proceedings, 2561. https://doi.org/10.1063/5.0113749

Priyotomo, G., Putrayasa Astawa, I.N.G. (2014). The Effect of Fe-Enrich Phase on The Pitting Corrosion Resistance of Al Alloy in Various Neutral Sodium Chloride Solutions. International Journal of Science and Engineering 7(2), 143-149.

Priyotomo, G., Nuraini, L., H. Gunawan, H., Triwardono, J., Sundjono, Prifiharni, S. (2021). A Preliminary Field Study of Antifouling Paint Perfomance After Short Exposure in Mandara Bali, Indonesia. International Journal of Engineering TRANSACTIONS A: Basics 34(04),976-986.

Priyotomo, G., Prifiharni, S., Nuraini, L., Royani, A., Sundjono, Gunawan, H. (2022). The Performance of Antifouling Paint for Prolonged Exposure in Madura Strait, East Java Province, Indonesia. International Journal on Advanced Science Engineering and Information Technology 12(2), 732-737.

Rodríguez, J.J.S., Hernández, F.J.S., and González-González, J.E. (2002). XRD and SEM studies of the layer of corrosion products for carbo steel in various different environments in the province of Las Palmas (The Canary Islands, Spain), Corrosion Science 44 (11), 2425–2438.

Sundjono, Priyotomo, G., Nuraini, L. (2017). The Selection of Magnesium alloys as Sacrificial Anode for the Cathodic Protection of Underground Steel Structure. International Journal of Engineering Trends and Technology 51(2),78-82.

Sundjono, Priyotomo, G., Nuraini L, Prifiharni S. (2017). Corrosion behavior of mild steel in seawater from northern coast of java and southern coast of bali, Indonesia. J Eng Technol Sci 49(6), 770-784.

Voulvoulis, N., Scrimshaw, M.D., Lester, J.N. (2002). Comparative environmental assessment of biocides used in antifouling paints. Chemosphere 47(7), 789-795.

Yebra, D.M., Kiil, S., Dam-Johansen, K. (2004). Antifouling technology—past, present and future steps towards efficient and environmentally friendly antifouling coatings. Progress in Organic Coatings 50(2),75-104.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Meifina Meifina, Gadang Priyotomo

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.